True confession here from a still novice builder. The day following the posting for Day 5, I was horrified to discover (by flipping the hull) the keel and rudder were not aligned perfectly. Apparently, one hole for the keel bolts was a”hair off” center when drilled. Knowing the sealant was not yet cured, I pulled all the pieces apart and wiped them clean with alcohol soaked rags. That effort took awhile, and put me back to Day 4. Not sure how to approach this problem, I contacted Cliff Martin. Cliff reassured me this was an easy fix, much to my relief. He suggested that I buy some 1/32” plywood and trace the keel shoe on it. Then, by cutting the plywood to the shape of the keel shoe, and placing it in the hull below the keel shoe, the holes would be sealed. From that point, my focus turned to making certain the new holes to be drilled would be perfectly aligned with the rudder. Today, I drilled the new holes with much care. Instead of using a 1/4” drill, I began with a 1/16”, then went to 1/8”, and on to 3/16”. After each drilling, I used a caliper to measure the alignment to a drawn center line. Final drilling was the 1/4” needed for the keel bolts. The caliper confirmed the holes were the same distance as the keel bolts. I then set the hull on the keel, flipped it, and saw that the alignment was perfect. Lesson to others: Drill holes with great care!!

So……back to the build after setting the keel shoe in place with sealant. Cure time will be 3 days.

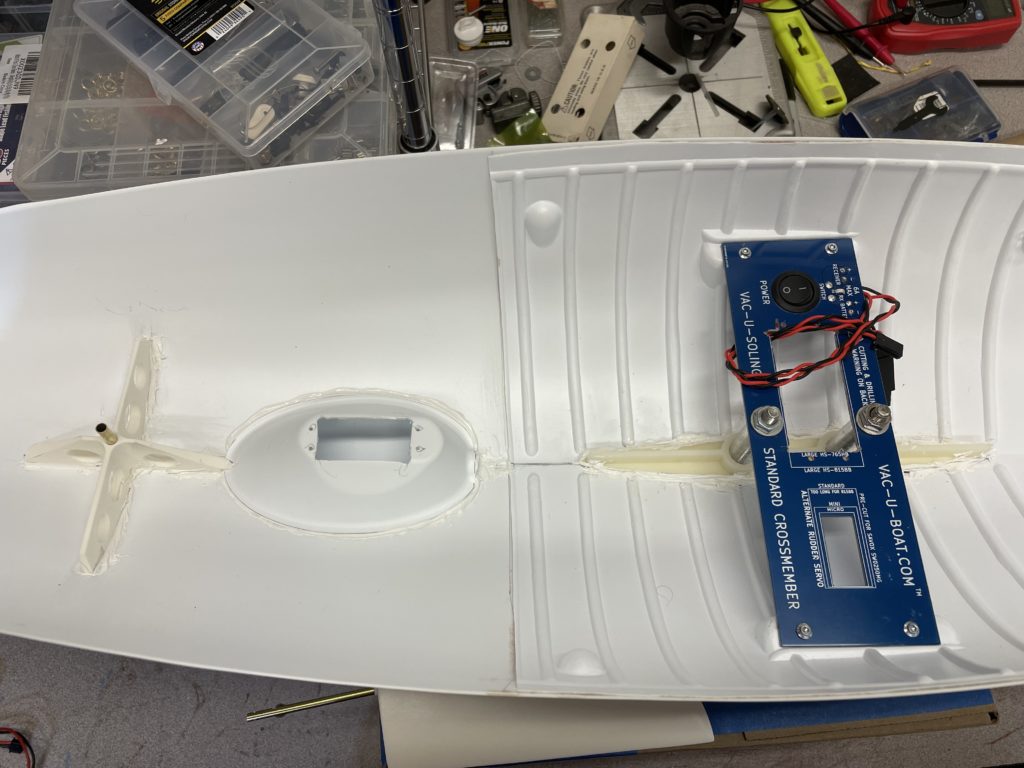

Last thing done today was the placing of the rudder servo mount. See photo!